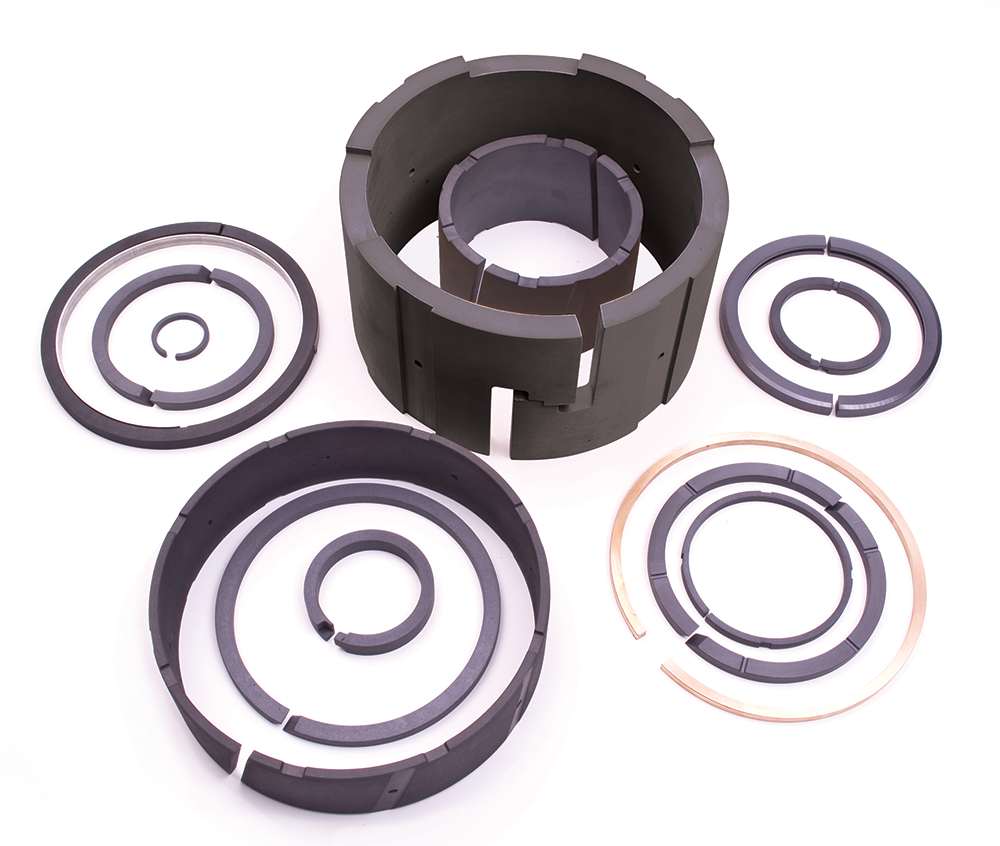

Material Processing Capabilities

In-House Materials Expertise

With complete in-house material blending and processing capabilities, Cook Compression has the flexibility and expertise to deliver custom solutions tailored for maximum performance in your applications. Cook Compression TruTech® materials are lab tested and field proven — and strictly controlled.

Compounding, compression molding, free sintering, injection molding and machining are all performed in-house and closely monitored to ensure the quality and consistency of finished products.

Cold Compression Molding and Free Sintering

The free sintering process is primarily used with PTFE-based material formulations.

Raw powder is mechanically blended in a controlled environment to produce a custom formulation. The blended powder is placed in a mold and subjected to a controlled pressure profile to produce a “green” pre-form. This pre-form is then placed in an oven where an engineered temperature profile is applied to consolidate the powder and optimize its bulk properties.

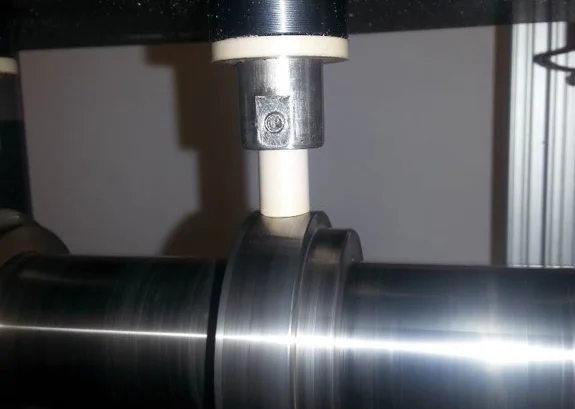

Hot Compression Molding

Hot compression molding is used for PEEK-based material formulations.

As in the cold compression process, raw materials are mechanically blended in powder form and cold pressed in a mold. The mold is then transferred to an oven to be heated above the material melting point. Pressure is applied again to the melted material.

Once the material is fully crystallized and consolidated under pressure, the part is removed from the mold and annealed to relieve internal stresses and maximize thermal and mechanical characteristics.

Injection Molding

Injection molding is primarily used with PEEK materials to form specified shapes.

The material starts in the form of pellets, which are first dried, then melted. The melted material is injected at high pressure into a mold cavity to cool and harden. A holding pressure is applied to compensate for thermal shrinkage.

Custom-Blended Materials

In-house precision blending capabilities enable Cook Compression to enhance specific material properties using reinforcements, fillers and additives.

In addition, our Materials Laboratory features state-of-the-art mechanical, chemical, optical and thermal analysis equipment that allows us to identify, differentiate and evaluate materials by their signature properties.