PET Bottle Blowing Compressor Solutions

Solutions for High Temperature Conditions

To generate the high pressure air required for PET (polyethylene terephthalate) bottle blowing, reciprocating compressors must take air from atmospheric pressure to about 600 psi (40 bar), usually in just three stages and at a relatively high speed. As a result, these non-lubricated compressors tend to run extremely hot.

Given the use of the end product as a beverage container, the facility must also maintain the highest standards of cleanliness for the compressed air.

Cook Compression offers a range of long lasting solutions for these high temperature environments – due in large part to our extensive materials expertise and development efforts.

Engineered Polymer Seals

The high temperatures and often wet air in PET bottle blowing are especially hard on the seal parts. Moisture can wash away the low-friction PTFE transfer film.

Cook Compression TruTech® P2210, a polymer alloy material for rod packing, piston rings and riders, is uniquely suited to these demands. It disburses heat more effectively off the rod and provides exceptional wear resistance due to its self-lubricating properties.

Even where other seals have failed, Cook Compression can provide a long-lasting solution, specially engineered to your application and operating conditions.

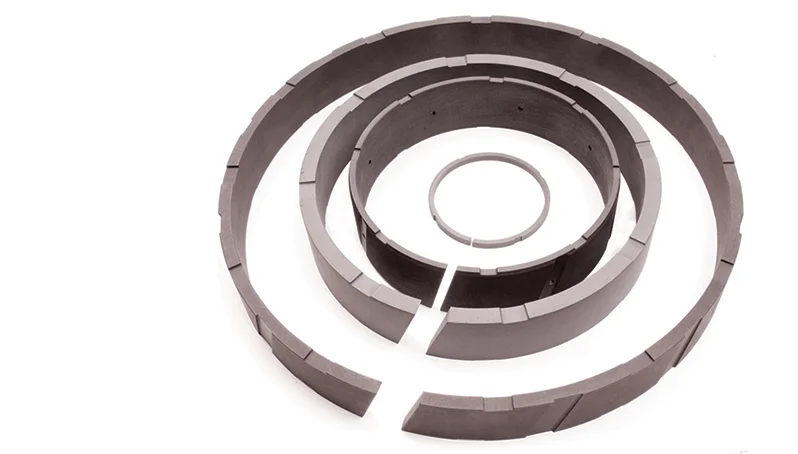

Ultra-Low-Leakage Packing Rings

Cook Compression addresses rod temperatures and sealing effectiveness with advanced rod ring designs. Our patented gapless packing ring design, for example, eliminates leak paths and reduces the frictional heat load, allowing packing assemblies to run cooler. This cooler operation can directly correlate to extended seal life.

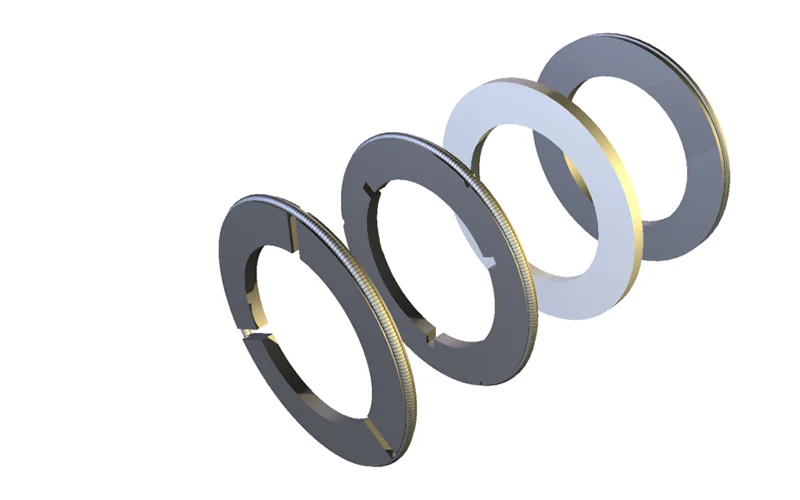

Steel and Thermoplastic Plate Valves

Cook Compression has a long history of supplying steel plate valves from its Optima™ Series to the PET air compression market. Cook engineers the valve to application-specific conditions and provides steel internals that can handle temperatures up to 662°F (350°C).

Optima Series valves with thermoplastic rings may also be used in the first compressor stages to improve valve life and reduce risk of cylinder damage.

Related Case Study

Upgrade Extends Run Times for PET Bottling Operation

At a plastic packaging manufacturer, compressor availability was a significant problem on two high-pressure air compressors. Experts from Cook Compression worked with customer maintenance personnel to understand the existing operation, as well as future service requirements for the compressors. Cook then developed a plan to retrofit upgraded components, including new high-performance rider bands.