Low-Emissions Rod Packing

Solid Sealing

Minimize reciprocating compressor gas leakage at its primary source – in the packing case along the piston rod – with Cook Compression low-emissions rod packing. The patented, gapless design eliminates leak paths, sealing more effectively and reducing fugitive emissions below measurable limits.

This helps operators comply with EPA requirements (GHG Reporting rule: Subpart W, 40 CFR Part 98) and boosts profitability by retaining valuable gas that would otherwise be lost through the vent.

Cooler, Longer Performance

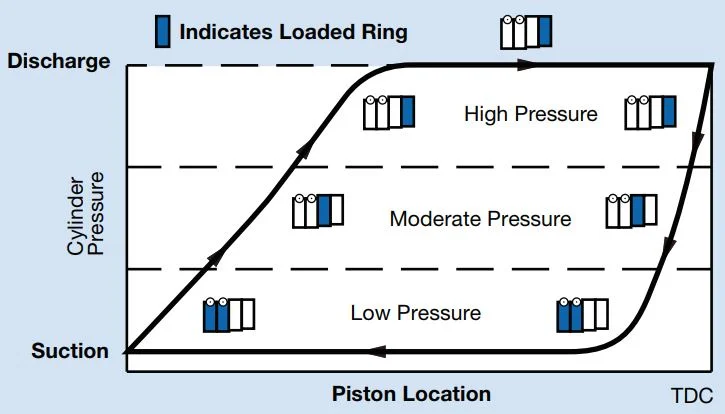

In each ring set, the rings seal sequentially based on pressure, minimizing the number of rings in contact with the rod at any one time and limiting the amount of time any single ring is in contact.

This sophisticated sealing mechanism reduces frictional heat load and allows packing assemblies to run cooler, which reduces wear, extends run times and decreases maintenance costs. Piston rod temperature reductions of up to 100°F (38°C) compared to traditional rings have been observed.

The increased sealing capacity of each ring set also allows fewer cups and rings to be used. The first ring set does most of the sealing, reducing the pressure applied to subsequent rings and eliminating wear.

Tailored Designs

Cook low-emissions rod packing is available in several configurations:

- BTUU® and CUU™ rings (sometimes referred to as solid ring or uncut ring technology) for neck-down compressor rods

- BTRR™ and CRR™ rings for other compressor rods

Rings are then engineered to each application. Design considerations include pressure drop between packing rings, packing ring geometry, and material selection for proper activation and loading of each ring.

Advantages

- Improves emissions compliance

- Retains valuable gas

- Increases efficiency

- Extends packing life

- Reduces downtime and maintenance costs

Related Case Studies